MECHANICAL DESIGN ENGINEER

In developing 9 medical devices,

I’ve learned to speak fluent CAD, fail fast with prototypes, and solve problems using systems thinking. I’m energized by learning new tech, collaborating across disciplines, and building human-centered products.

Welcome!

I’m excited to share my work with you.

I’ve always loved building—whether it was constructing decks with my dad as soon as I could handle a power drill, or machining parts for a competitive off-road race car in college.

But it was through a design thinking course that I began to discover my natural passion: bringing ideas to life through user-centered design.

This fueled my drive to develop medical devices while collaborating with surgeons, pharmaceutical scientists, and fellow engineers. In these roles, I embraced ownership of mechanical designs, eager to propel healthcare innovations forward.

Now, I’m looking to join a product development team, excited to continue learning, building, and collaborating in a multidisciplinary team transforming ideas into human-centered products!

Let's ConnectSome of my work.

Engineering across academia & industry.

Conferences:

Journal Articles:

Mechanical Engineering

-

Sheet Metal (aluminum)

Machining (steel, aluminum, nylon)

Rapid Prototyping (SLA, FDM, MJF, PolyJet 3D Printing)

Waterjet & Laser cutting

Plastic Extrusion (PTFE tubing)

Thermoforming (ABS)

Polymeric Composites Fabrication (silicone mediums, polystrene microspheres)

-

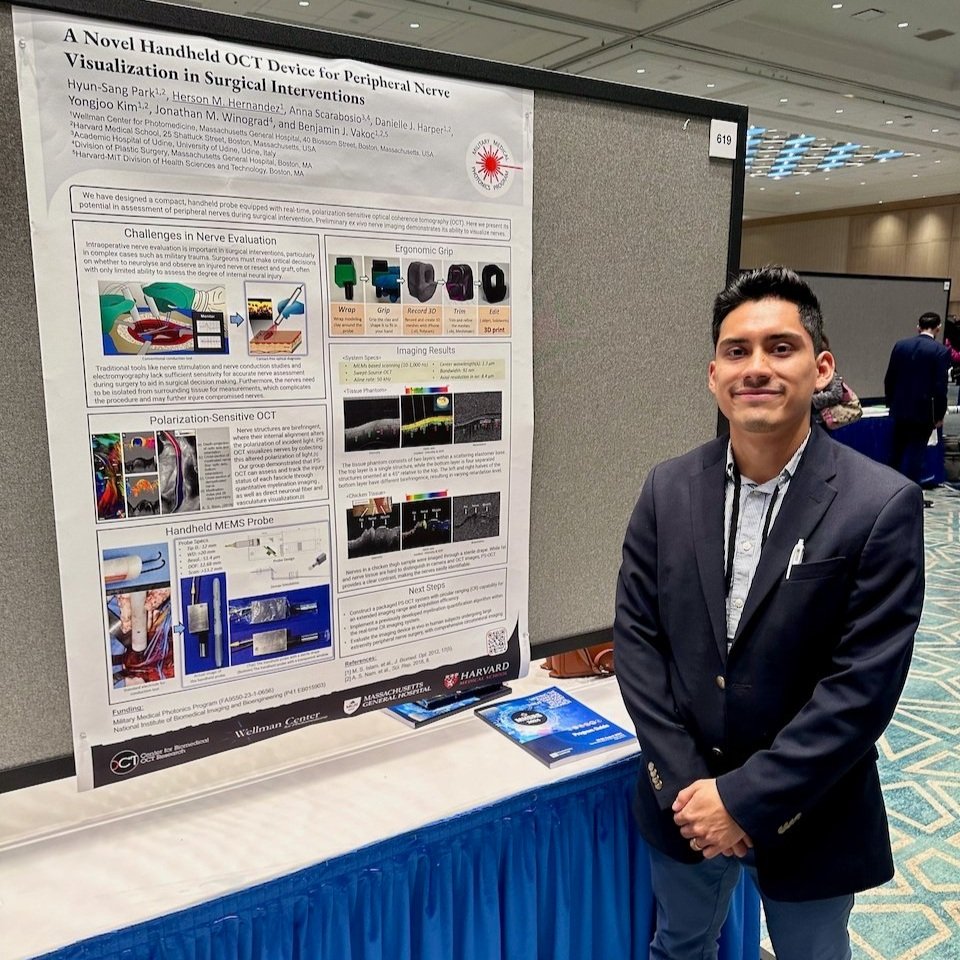

Led mechanical design, fabrication, and testing of complex electromechanical systems, integrating optical, MEMS, and electrical components.

Ensured performance through structural, thermal, vibration, and optical analyses.

-

Diagnosed and resolved design challenges through FEA, statistical analysis, and hands-on debugging, improving system reliability and manufacturability.

Medical Technology

-

Endoscopic catheters

Handheld and mounted surgical imaging tools

Surgical robots

Medical cart

-

Conducted user research, developed needs assessments, and defined system requirements to align medical device design with clinical needs.

-

Surgeons (gastroenterology, neuro, dermatology, ENT)

Pharmaceutical scientists

Manufacturers & Vendors

Optical engineers / SMEs

Mechanical & Electrical engineers

Product Development

-

Partnered with assembly technicians to streamline production, developing custom assembly tools and build fixtures for efficient manufacturing.

-

Created 20+ documents for Design History Files (DHFs)

Executed Design Verification Testing for 2 surgical robots and upper-limb prosthetics

Created traceability matrices

ISO Risk Management

-

Managed project timelines and budgets to drive research-to-market success.

Applied structured decision-making (Pugh matrices), rapidly generated product renderings with SolidWorks Visualize, and presented design recommendations to stakeholders.